Laser Cutting Acrylic: All You Need to Know

Acrylic is an eye-catching material because of its shiny appearance, transparency, optical clarity, and beautiful colors. Because of its mesmerizing properties, it is used in a wide variety of products that remain in great demand.

On the markets, acrylic is available in sheets. With that being said, you need to cut the desired shape or pattern out of the sheets to make whatever you want. There are various options for cutting acrylic, but laser cutting is the most preferred option because it offers perfect and fine results that add more beauty to the final product.

However, if you want to laser cut acrylic, you need to learn a lot of things before your first attempt. Therefore, we are here with a comprehensive guide on laser cutting acrylic.

In This Article

- Types of Acrylic

- Can You Laser Cut Acrylic?

- Laser Cutting Acrylic Projects for Your Inspiration

- Best Acrylic Laser Cutting Machine Laserbox Rotary(CO2)

- FAQs: Learn More About Laser Cutting Acrylic

Types of Acrylic

Basically, there are two types of acrylic based on how their sheets are made. These are commonly known as Cast Acrylic and Extruded Acrylic.

Both these acrylic types are available in the form of sheets, but their manufacturing is different. Surprisingly, they both have the same chemical composition, but they show different properties under a laser machine. Therefore, it is better to understand how these acrylics are made and which you can select for laser cutting.

Cast vs Extruded Acrylic for Laser Cutting

Cast acrylic is made by pouring molten acrylic into a mold. The mold gives the required shape, size, and thickness. It is quite easy to make cast acrylic in the desired shape, as a suitable mold is the only thing required.

Cast acrylic is preferred for engraving. The reason behind it is that when it is engraved, it offers a white frost look that makes engraving more than appealing. The commonly available engraved products on the market, such as photos, keychains, and awards, are usually made from cast acrylic.

It is not preferred for cutting because it does not produce fine edges. However, it can still be cut and offer good results if the power and speed of the laser machine are controlled.

The second type of acrylic is known as extruded acrylic, which is made through mechanical pressing on the hot acrylic sheet under rollers. The acrylic is rolled until the desired thickness is achieved. It is a continuous production process, and acrylic sheets are made in large volumes, which is why extruded acrylic is cheaper than cast acrylic.

Extruded acrylic is considered ideal for cutting. It offers perfectly fine edges when cut through a laser. The reason behind it is the mechanical pressure applied to the acrylic in the production. This type of acrylic is not used for engraving because it does not offer a frost-like appearance when engraved. The engraving remains clear, which is not clearly visible. Therefore, if you are looking for engraving, this is not the right option.

If you want to engrave acrylic, you can choose cast acrylic. It can also be cut through the laser to get the desired shape of the sheet. It is suitable for DIY purposes and making a wide range of products.

We have seen the classification of acrylic based on its manufacturing. But acrylic can also be classified based on color, thickness, mirroring, light diffusion, tint, texture, radiation blockage, etc. You can get almost any type of acrylic you want for your project.

Can You Laser Cut Acrylic?

This is one of the most frequently asked questions related to acrylic. Let’s look at the process of acrylic laser cutting to understand how it works.

In laser engraving or cutting, powerful laser beams strike the surface of the material and increase its temperature in no time. Due to the sudden rise in temperature, the material changes to a gaseous state from solid. However, it depends on the type of material you are engraving and its boiling temperature.

Acrylic is a material that directly changes to the gaseous state from the solid when its temperature quickly reaches the boiling point. It is because the boiling point of acrylic is only 200°C. Laser engraving machines can quickly increase the temperature of acrylic, so it directly changes to fumes. The material from the surface evaporates and leaves a cavity or deep mark. This deep mark is known as engraving.

Laser machines can also cut acrylic. They can easily pass through the sheet if appropriate power and speed are selected. The material is turned into fumes in no time.

It is a very simple answer that a laser can cut or engrave acrylic, but there are other things to be considered, such as the type of laser machine and the type of acrylic and color.

Acrylic laser cutting or engraving depends on the wavelength and color of the laser. For instance, if the color of the laser is blue, it won’t be able to cut blue acrylic. The reason is that it is of the same color. The blue color reflects the blue laser, which means it is not absorbed and cannot increase the temperature of the material. Therefore, it cannot cut blue acrylic.

Similarly, clear acrylic cannot be cut using a blue laser. The laser beams directly pass through the acrylic without being absorbed. Thus, there is no way laser cutting clear acrylic can be done through a blue laser.

For these special cases, you need to use a suitable laser. A CO2 laser is the right option because it emits laser beams that are in the infrared region. These beams can be absorbed in clear acrylic as well as blue acrylic.

Another important factor of the laser machine is power. If the laser machine is capable of delivering enough power, it will easily cut acrylic. Otherwise, there will be fewer cuts required, and it is preferred to cut it in only one pass because it takes less time and offers the best results.

Users prefer laser machines for acrylic cutting because they can offer perfect results in less time. Secondly, it is versatile, which means it can cut as well as engrave acrylic. With the help of a laser machine, you can cut acrylic of any shape from the sheet. Even at high-speed, it gives fine results.

What Type of Acrylic is Best for Laser Cutting

There is no question that a laser machine can easily cut acrylic. But as there are many types of acrylic, different laser machines, and other variables, it is important to know which type of acrylic is best for laser cutting.

Almost all types of acrylics can be cut using a laser machine, depending on the power and speed. Extruded acrylic is preferred for cutting, but the problem is that you cannot engrave it. Therefore, if you want to do engraving on acrylic and cut the desired shape, you can go with cast acrylic. It is suitable for cutting and ideal for engraving.

While choosing acrylic for cutting, you also need to consider the color and thickness. If you are using a CO2 laser, you can cut any color of acrylic. The blue laser cannot cut blue and clear acrylic, so you need to avoid them if you have a blue laser machine.

The thickness of acrylic also matters. Depending on the power of the laser machine, you need to select a suitable thickness. A 20W diode laser can easily cut up to 8mm acrylic in one pass. CO2 lasers are more powerful, so they also cut the commonly available acrylic sheets.

9 Laser Cutting Acrylic Projects for Your Inspiration

There are tons of ideas out there, and you can also brainstorm some cool and extraordinary ideas and implement them using your laser machine. Here are a few ideas for your inspiration.

1) Laser Cutting Acrylic Earrings

Using acrylic, you can make distinct, attractive, and fashionable earrings and other jewelry items. You can cut and engrave almost any design on acrylic, and due to its shiny appearance and diffusion and reflection of light, it looks awesome.

There are various designs available for different occasions, such as Christmas, Halloween, National day, and St Patrick’s day. You can make almost any kind of design, and the best part is that it costs you almost nothing. After engraving and cutting, you only need to attach the earring hoops and hooks.

On special occasions, these earrings are in great demand. You can also find other stylish and unique designs or create your own.

2) Acrylic Laser Cut Signs

Acrylic cut signs are in great demand. You might have these signs in offices, buildings, homes, etc. These are used for branding, designing the main sign of the business, symbols, nameplates, etc. There is a massive demand for these signs on the market.

You can make any type of design using the laser machine, but its size depends on the working area. However, you can still make a wide range of designs and signs. For instance, you can make door signs, LED wall signs, table signs, etc.

You can also cut logos and brand names from acrylic and use them to make signs for brands and businesses.

3) Awards & Trophies

The most common and preferred use of acrylic is in the making of awards. You might have seen shields and awards at different conferences and events. These are usually made from acrylic. The main part of the award is acrylic, and it is cut and engraved using a laser machine.

These awards have a huge demand in schools, offices, corporate events, businesses, etc. Creating such an award is pretty easy, as you only need to cut and engrave acrylic. You can make the base of the award using acrylic, wood, or any other material.

Pre-made awards are also available. So, you only need to engrave them and write whatever you want.

4) Acrylic Keychains

You can make customized keychains using acrylic sheets. It is one of the most common ideas, and people love to buy such keychains. It will cost you minimal, but the profit margin is excellent.

You can cut the keychains in the desired shape and then engrave the name, logo, photo, date, design, or anything else. There are also pre-made keychains available on the market, and you only need to engrave them.

Secondly, you can make celebrities, cartoon characters, and other keychains from scratch. You only need to cut two identical shapes from the acrylic sheet. Then, you can paste a sticker between them. Your keychain will be ready after adding the keychain ring.

5) Christmas Baubles

Christmas baubles are one of the hot-selling items on occasion. These are used for house decoration and Christmas tree decoration. People frequently buy these from online stores.

Acrylic baubles look more attractive because of their color and customization. You can customize the baubles for the whole family and make a complete set. There are dozens of designs of baubles available for different occasions, such as Halloween and Christmas.

6) Wedding Invitation

If you are looking for a distinct wedding invitation, then this could be the right choice. Acrylic wedding invitations look more than appealing. These are different, and they look classy. You can make wedding invitations for others. All you need to do is cut the invitation in the desired shape and then engrave it.

To make it more appealing, you can use foil writing on transparent acrylic. It looks more than exceptional. The best thing about it is that the person who will order the invitation will definitely order several pieces for distribution. So, you can make excellent profit from this idea.

7) LED Lamp

An LED lamp is a beautiful item that everyone would love to have in their home. You can make eye-catching lamps using acrylic. The LED blanks are available on the market, and you only need to cut and engrave acrylic. Then, finally, place the acrylic over the lamp. It looks mesmerizing, and people buy it for their bedrooms, living room, and gifting.

The design of the lamp depends on your creativity. You can make almost any design. Customized designs can be made for couples and families. You can write names on the acrylic sheet. Special LED lamps can be made for special events, such as Christmas, Halloween, weddings, and housewarming parties.

8) Toys

Acrylic can also be used to make toys for kids. You can cut puzzles or DIY toys using acrylic sheets. It is a great activity for children to join all the parts of the puzzle or toy. You can make a plane, jigsaw puzzle, cartoon character, and similar things. There are various options to make.

These toys are not only for kids but they can also be used as décor items. You can keep it in your house or office.

9) Cake Toppers

Acrylic cake toppers do not need an introduction. These are the must-haves on every birthday or celebration. You can make beautiful acrylic cake toppers using the sheets. It is one of the simplest ideas that beginners can also try. If you want to sell these like hotcakes, make sure to introduce some new designs that are unique and appealing.

Best Acrylic Laser Cutting Machine Laserbox Rotary(CO2)

xTool’s Laserbox Rotary is a 40W CO2 laser machine, which is ideal for acrylic cutting. If you are looking for a desktop acrylic cutting machine for your home, DIY, or small business, this machine is the best option because it offers enough optical power and all features you need.

Since the machine is a CO2 laser, it can be used to cut almost any type of acrylic at a very fast speed. It makes acrylic cutting easier. With this machine, you make almost anything, including awards, keychains, and tons of other acrylic products, with perfection. Other than acrylic, the machine can engrave wood, glass, leather, cardboard, metal, paper, stone, food, rubber, fabric, etc.

The problem with laser acrylic cutting is the harmful smoke. Laserbox Rotary is an enclosed machine, so the fumes do not come out of it, and there is no need to buy a separate enclosure. Secondly, it has a built-in smoke purifier system that works according to the volume of the smoke produced inside the machine. It purifies the fumes and ensures the exhaust is eco-friendly. You can also attach the ventilation system to the machine to throw gasses and debris out of the working area.

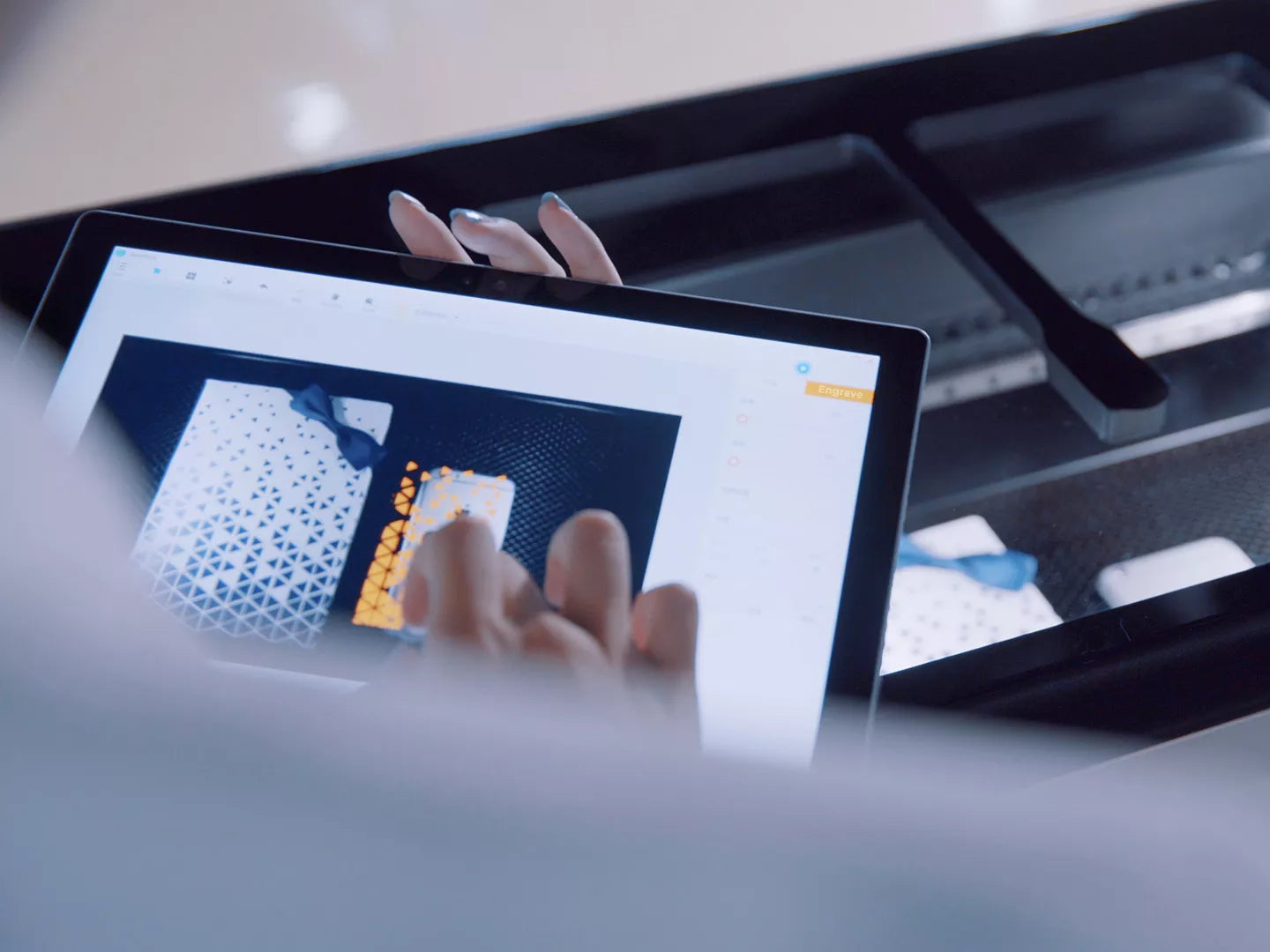

Laserbox Rotary is a pack of extraordinary features. It has some exceptional built-in features that make laser engraving and cutting easier and a bit of fun. It has a built-in camera that gives you a live preview of the working area and the object. You get real-time results for perfect engraving and cutting. It also helps in the exact position of the graphics over the object.

The AI focus of the machine focuses on the object automatically by identifying the object and its thickness. It gives the optimal settings that help you achieve the results you need. The incredible feature of the machine is smart path planning. It gives you a preview of the cutting and engraving paths before starting. You get a complete idea of the final product and can easily rectify the fault if there is any.

Through the image extraction feature, the image from any object is copied to the software. Then, you can use the same image on your projects. Even your hand-drawn images can be used for engraving and cutting. You can also get the rotary attachment for the machine to engrave cylindrical objects, such as tumblers and mugs.

The machine is completely eco-friendly and safe. It has various safety features. If the lid of the machine is opened in the middle of the work, it stops automatically. Secondly, you get immediate alerts for overheating, water cooling, and safety. Even children can operate this machine under the supervision of teachers and guardians.

Laserbox Rotary is a complete package that can engrave and cut acrylic and a wide range of other materials. It is suitable for beginners that want to start a small business or use the machine for other purposes. It is compact, efficient, and safe, and due to its advanced features, it is ideal for laser engraving and cutting.

FAQs: Learn More About Laser Cutting Acrylic

1) What Setting to Use When Laser Cutting Acrylic

It is almost impossible to tell the exact settings for laser cutting acrylic because it depends on various factors. Firstly, it depends on the optical power of the laser machine. For instance, if a 10W laser machine can cut 2mm acrylic at 80% power and 100mm/s, then a 20W laser will cut the same acrylic at 40% power.

Secondly, the selected speed also matters a lot. If the speed is too high, the laser won’t be able to cut through the acrylic. The right combination of speed and power is necessary, and no one can tell that.

Another variable is the thickness of the acrylic sheet. The settings vary according to that. Simply put, you cannot get the exact settings to get the best results without considering the variables.

There are thumb rules and commonly used values for different cases, but it is better to have a power and speed test on the material first. It will give you a complete idea of the right power and speed that is suitable for your project. Otherwise, you will end up wasting the acrylic sheet.

2) Tips for Laser Cutting Acrylic

For excellent results, optimal safety, and saving money, here are some useful tips you can adopt for laser acrylic cutting.

- While selecting the laser machine, make sure it has enough power to cut acrylic at a fast speed. If you can afford a CO2 laser, it is the best option. Otherwise, a diode laser is the next option for acrylic cutting.

- There must be proper ventilation when cutting or engraving acrylic. These fumes are harmful, so they must be purified and expelled through a proper ventilation system.

- Choose the right material before engraving or cutting. For the perfect settings, run a speed and power test on the material.

- The material should be focused if you want to get the best results.

- You must use air assist with the machine. It blows away the fumes produced and the debris to keep the object clean

3) Can a Diode Laser Cut Acrylic?

Yes, a diode laser can also cut acrylic. But keep in mind that you also need to understand the limitations of the colors of acrylic. If you have a blue laser, you cannot engrave or cut blue acrylic with that. The material will not absorb the laser beams due to the same color. Secondly, almost all diode lasers cannot engrave clear acrylic. However, some users apply paint over the surface of the acrylic so that the laser cannot get reflected or pass through the acrylic. This method works, but it is not feasible every time.

The second thing that should be considered for acrylic engraving using diode lasers is the optical power. The machine should have enough optical power to cut the acrylic in one pass. The best option is a 15-20W diode laser to cut acrylic up to 6-8mm in one pass.

4) How Thick of Acrylic can a Laser Cutter Cut?

The thickness of the acrylic is also a variable factor that determines whether the laser machine can cut it or not. It depends on the optical power of the laser machine. A diode laser of 20W can cut acrylic up to 8mm in one pass. At the moment, 20W is the most powerful diode laser in the world, so you cannot expect more optical power from diode lasers.

CO2 lasers are a better option for laser cutting. They are more powerful and can easily cut thick acrylic sheets in one pass. A 40W can CO2 laser machine can cut up to 20 mm thick acrylic or sometimes even more. It depends on the manufacturer of the machine and the rated laser optical power. You can also get more powerful CO2 laser machines.

![Laser Cutting Paper: The Ultimate Guide [2023]](http://www.xtool.eu/cdn/shop/articles/001_520x500_8b573316-9cbf-4e67-ac4f-19897c63b1a7.jpg?v=1683873841)