Laser cutting is a highly precise and versatile method of cutting various materials, from wood to plastics to metals. Laser cutting is widely used in industries such as manufacturing, aerospace, and automotive, as well as in DIY and artistic projects.

In this blog post, we will explore the world of laser cutting, including how it works, the types of materials it can cut, and its applications. We will also dive into the advantages of laser cutting, as well as some tips for getting started with laser cutting.

Whether you're a seasoned professional or just curious about this fascinating technology, this post will provide a comprehensive introduction to laser cutting.

Table of Content

- Advantages of Laser Cutting and Engraving Fabric

- What Types of Fabric and Textile Can be Laser Cut/Engraved?

- Applications of Laser Processing Fabrics and Textiles

- Choosing the Right Laser Cutting Machine for Fabric and Textile

- Best Laser Cutter for Fabric and Textile

- Tips for Getting the Best Results for Laser Cutting and Engraving Fabric

- Conclusion

What is Laser Cutting? How Does It Work?

Laser Cutting refers to the process that is used to cut materials and objects using a high-powered and extremely focused laser beam.

With lasers, different processes are carried out, including laser engraving, laser marking, laser cutting, and other processes that include physical alteration of materials. But cutting is a quite different process that cuts the materials into pieces.

The laser beams with intense power are encapsulated in the laser module and consist of electromagnetic radiation of a certain wavelength which can be invisible to the naked eye, such as infrared radiation in a CO2 laser cutter.

The beams are then passed through several bending mirrors and reflectors before converging at a single spot having a diameter in fractions of a millimeter through a convex lens.

Accompanied by a fast-moving gas, usually Nitrogen or Oxygen, the highly focused laser beams come out from a nozzle and are directed by computer numerical control (CNC), which makes the process also known as CNC laser cutting. The computer program moves the laser head/module according to the requirement.

When the laser beams land on the material, the temperature of the material increases within milliseconds, causing sublimation, a process in which a material changes from a solid to a gaseous state without passing through the liquid state.

The material then vaporizes, and the laser beams penetrate the object to cut it into the desired shape. The process can be completed in one pass if the laser beams are powerful enough; otherwise, several passes are needed.

In summary, laser cutting is a highly precise and efficient process that utilizes a focused laser beam to cut materials. The process involves the use of a highly-focused laser beam and computer numerical control (CNC), which work together to achieve the desired result.

Materials Suitable for Laser Cutting

Laser cutting is a popular technique for cutting and engraving various materials, such as wood, acrylic, metal, leather, and more.

However, not all materials are suitable for laser cutting, and some may require specific types of laser cutting machines.

Here are some materials that are suitable for laser cutting:

1. Wood: Laser cutting is an excellent technique for cutting wood, including plywood, MDF, and solid wood. It can create intricate designs, patterns, and shapes with precision and speed.

Wood laser engraving is also possible with a laser, allowing for custom artwork and personalized gifts.

2. Acrylic: Acrylic is a popular material for laser cutting due to its versatility, durability, and aesthetic appeal, , making it a popular choice for applications that require an attractive and aesthetically pleasing finish, such as awards, trophies, sinage, display, and decorative items.

3. Leather: Laser cutting can produce intricate and precise designs on leather with minimal waste. It is commonly used in the fashion industry for cutting leather patterns, bags, and accessories.

4. Plastic: Laser cutting is suitable for various plastic materials, including acrylic (PMMA), polystyrene (PS), polyethylene (PE), polypropylene (PP), etc. It can create precise shapes and designs for signage, displays, and packaging.

It is essential to note that different types of plastic have varying melting points and react differently to laser cutting. Therefore, it is essential to consult with the laser cutting machine's manufacturer or supplier to ensure the plastic material is suitable for laser cutting.

Additionally, it is crucial to take precautions when cutting plastic materials as they can release harmful fumes when exposed to high temperatures.

5. Paper and cardboard: Laser cutting is perfect for creating paper and cardboard prototypes, pop-up cards, and intricate designs.

6. Fabric: Laser cutting can create clean cuts and precise shapes on various types of fabric, including cotton, silk, polyester, and leather. It can be used for fashion, upholstery, and decorative items.

7. Metals: Metal cutting with a laser is suitable for thinner materials such as stainless steel, aluminum, brass, and copper. It can also engrave on coated or anodized metals.

8. Rubber: Laser cutting is ideal for cutting rubber materials, including silicone rubber, neoprene rubber, and natural rubber. It is used in the automotive, industrial, and medical industries.

9. Foam: Laser cutting is perfect for cutting foam materials, including foam rubber, EVA foam, and polyurethane foam. It can create precise shapes and designs for packaging, cosplay costumes, and props.

Compatible Materials for Different Laser Cutting Machines

Also, different types of laser cutting machines are suitable for specific materials due to their specific characteristics, including the material's thickness, density, melting point, and reflectivity. The following are some examples:

1. CO2 lasers: CO2 lasers are commonly used for cutting non-metallic materials such as wood, acrylic, paper, and fabric.

CO2 lasers have a wavelength of 10.6 microns, which is well-suited for these materials as it is efficiently absorbed, resulting in clean and precise cuts.

The power of CO2 lasers ranges from 30 watts to 400 watts, making them suitable for cutting various thicknesses of non-metallic materials.

2. Fiber lasers: Fiber lasers are ideal for cutting metals such as stainless steel, aluminum, copper, and brass.

Fiber lasers ususally have a wavelength of 1.06 microns, which is efficiently absorbed by metal, resulting in a clean cut. Fiber lasers have high power, making them suitable for cutting thicker metal sheets.

3. Diode lasers: Diode lasers are commonly used for cutting thin and soft materials, such as paper, cardboard, and thin plastic films.

Diode lasers have a wavelength of around 455-1064 nam, which is efficient at cutting these materials. They are often used in small and compact laser cutting machines that are suitable for hobbyists or small businesses.

4. UV lasers: UV lasers are suitable for cutting materials that are difficult to cut with other laser types, such as glass, ceramics, and certain plastics.

UV lasers have a shorter wavelength of 355 nanometers, which is efficient at cutting these materials.

Materials That Can Not Be Cut with Laser Cutting

While laser cutting is a highly versatile and efficient method of material processing, there are some materials that are not suitable for laser cutting due to either their harmful fumes emissions or poor cutting results.

Here are some examples of such materials to be cautious of when considering laser cutting:

1. PVC and Vinyl: Cutting PVC with a laser produces hydrochloric acid gas, which can damage the laser and pose a health risk to those in the vicinity. PVC should be avoided or cut using alternative methods.

2. Polycarbonate: While polycarbonate is transparent and impact-resistant, it tends to melt and produce rough edges when cut with a laser. Other cutting methods, such as sawing or routing, are better suited for this material.

3. Glass: Glass is difficult to cut with a laser machine as it requires a lot of power, and it can shatter during the process.

By being aware of these limitations, you can avoid potential safety hazards and ensure optimal cutting results. It's always important to consult with a professional or the material manufacturer to determine the most appropriate cutting method for a specific material.

Advantages of Laser Cutting

As explained above, laser cutting uses a high-powered laser beam to cut various materials and is directed by computer numerical control software, which achieve numerous advantages over traditional methods.

Laser Cutting Produces High-qualtiy Resutls

Due to the small size of the laser spot, high energy density, and fast cutting speed, laser cutting can achieve good cutting quality - precise and clean cuts.

The highly-powered and focused laser beam produces a very narrow kerf (cutting width) that vaporizes the material being cut, resulting in minimal material waste and producing a clean and smooth edge, with a surface roughness of only a few tens of micrometers.

Laser cutting can even be used as the final process without the need for mechanical processing, and the parts can be used directly.

Additionaly, the width of the heat-affected zone is very small, the properties of the material near the cutting edge are almost unaffected, and the deformation of the workpiece is small.

Laser Cutting Machines Process Automatically and Quickly

Laser cutting is an automated process. After you upload the design to the software and adjust the optimal laser beam's power, speed and focus settings based on the material being cut, guided by the control software, the laser beam moves quickly and efficiently, which can make thousands of cuts per minute.

Laser Cutting is Incredibly Versatile

Compared to other conventional processing methods, laser cutting has greater adaptability.

First, compared to other thermal cutting methods, as a thermal cutting process, other methods cannot act on a very small area like a laser beam, resulting in wide cuts, large heat-affected zones, and significant workpiece deformation.

In addition, laser can cut non-metallic materials, while other thermal cutting methods cannot.

Laser cutting can cut a wide range of materials. Besides, the laser beam can be adjusted to suit different thicknesses, making it a flexible process that can be used for a variety of applications.

Additionally, laser cutting machines can be used to create complex shapes and designs, engrave logos or designs, and even create 3D structures.

This versatility makes laser cutting a popular choice in many industries, from automotive and aerospace to jewelry making and gift making, you can even start a small business selling laser-made products.

Laser Cutting is an Non-contact Process

When laser cutting, the material being cut is not touched by the laser cutting machine, which means there is little risk of deformation or damage to the material, making it ideal for applications where precision and quality are critical.

Laser Cutting Applications

Laser cutting is a highly accurate and efficient technology that has found its way into various industries such as manufacturing, automotive, aerospace, construction, medical, and textiles.

With the advent of compact and affordable laser cutting machines, this technology has become increasingly popular among DIYers, hobbyists, artists, and designers as well.

It is being used for crafting, DIY projects, and even for running small businesses. Here are some examples of the diverse applications of compact and desktop laser cutting machines in various industries:

Arts and Crafts

Laser cutting has become a favorite tool of many artists and crafters due to its precision and versatility.

Laser cutting machines can be used to create intricate designs on a variety of materials such as paper, cardboard, leather, and wood. From jewelry making to paper crafting, laser cutting can produce stunning and unique designs.

Home and Decor

Laser cutting machines are also being used by homeowners and interior designers to create unique home decor and furnishings.

From laser-cut wall art to personalized wooden signs, laser cutting machines allow for the creation of custom decor and furnishings that reflect the homeowner's personal style.

Fashion and Textiles

Laser cutting machines are becoming increasingly popular in the fashion and textiles industry.

image credit: Whenthebeestingsusa - Etsy

They can be used to cut and engrave a variety of fabrics and textiles, creating intricate designs and patterns. Laser cutting can be used to produce custom clothing, accessories, and even footwear.

Signage and Branding

Laser cutting is an effective way to create custom signage and branding materials for businesses.

This technology allows for the creation of intricate designs and letters that would be impossible to achieve with traditional methods. Laser cutting is used to produce signage, lettering, logos, and branding materials such as business cards, brochures, and packaging.

Jewelry Making

Jewelry designers can use laser cutting machines to create intricate and precise designs on a variety of materials such as metal, acrylic, and wood. The technology also enables the production of custom jewelry pieces with personalized designs for wedding rings, necklaces, bracelets, and more.

Wedding Decor

Laser cut designs on table settings, wedding invitations, and decorative pieces can give a unique and personalized touch to the wedding decor. The technology can also be used to create custom laser-cut wedding favors and gifts for guests.

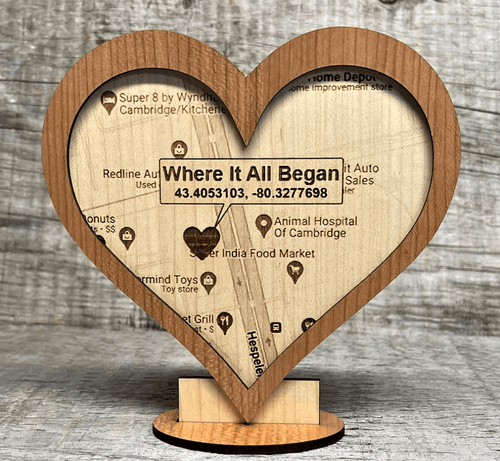

Gift Making

For gift making, laser cutting machines allow for the creation of custom designs on a variety of materials such as wood, leather, and acrylic. From personalized keychains to custom wooden plaques, laser cutting can help create unique and memorable gifts for any occasion.

Choosing a Laser Cutting Machine

Types of Laser Cutting Machines

Understanding the different types of laser cutters is crucial because each type is suitable for specific materials. There are four main types of laser cutters: CO2, crystal, fiber, and diode.

CO2 Laser Cutting Machines

In the CO2 laser, the laser beam is produced inside a sealed gas tube that contains a mixture of gas. The higher proportion of the gas is CO2.

The tube has two electrodes connected at the ends. When a high potential difference is created between the electrodes, the positive nucleus and electrons start to move in particular directions.

Due to the release of high energy from atoms, laser beams are produced from the tube. The beams are then reflected using mirrors and reflectors and converged using a convex lens.

The radiation emitted from CO2 lasers is invisible as it is in the infrared region. It is ideal for cutting and engraving non-metals, such as wood, plastic, paper, and fabric.

Fiber Laser Cutting Machines

Fiber laser cutters are more advanced than CO2 laser cutters as they are newer and equipped with the latest technology. Consequently, they are very expensive.

Fiber lasers are based on seed lasers, in which a laser is generated using a bank of diodes and then amplified. For amplification, fiber lasers use glass fibers, so the resultant laser beams are 100 times more intense than CO2 laser beams.

Due to the intense and high energy of the laser beams, they can easily cut metals, such as stainless steel, copper, and aluminum.

Fiber laser cutters are very efficient. They are nearly four times more efficient than CO2 laser cutters. The reason behind high efficiency is the use of glass fibers that convert 75% of the power into laser beams and reduce the power loss.

Thus, fiber laser cutters are more powerful and intense than CO2 lasers of the same rated optical power. They also cut materials at a faster rate.

Diode Laser Cutting Machines

Diode lasers are also called semiconductor lasers because diodes are made of semiconductors. As the name suggests, diodes are used to create laser beams in this type of laser.

The diodes used for producing lasers are a bit different from common diodes. They have a special intrinsic layer that gives off high-energy photons, which are then amplified into a laser.

The working of these lasers is pretty simple. The diode banks emit laser beams which are then reflected using a reflector.

If there are multiple diode lasers in a module, all the beams are converged using a convex lens. Once they pass from the convex lens, they are highly directional and focused, then they are ready to cut and engrave objects.

Diode lasers are quite popular and widely used these days. They are widely used for DIY projects and creating various products.

They are excellent for cutting wood, opaque acrylic, and a few other materials. They can engrave wood, steel, leather, glass, rubber, acrylic, cardboard, ceramics, etc.

The materials for cutting are limited because these are not as powerful as other laser types. Usually, the laser optical power is 10W or lower; however, we have introduced a 40W diode laser module, which is the world’s most powerful diode laser module.

Typically, these are not suitable for translucent and reflective materials, such as metals. You cannot use them for metal cutting. However, they are excellent for cutting wood and acrylic for small projects. Due to low power, the speed is also lower than other laser types.

Diode lasers are very compact and lightweight. They are much more affordable and have a longer lifetime than other types of lasers, which is why they are quite common and preferred for startups and small businesses.

![Laser Cutting Paper: The Ultimate Guide [2023]](http://www.xtool.eu/cdn/shop/articles/001_520x500_8b573316-9cbf-4e67-ac4f-19897c63b1a7.jpg?v=1683873841)